Nekuenderera mberi nekudzika kwechido chehungwaru zvinhu, iyo ina-nzira yekuvhara matatu-dimensional warehouse ine mapallets yakagadzira kuita imwe yemhando huru dzekuchengetera zvinhu nekuda kwemabhenefiti ayo mukuita uye kwakaoma kuchengetedza basa, mutengo wekushandisa, uye yakarongeka yakangwara. manejimendi mukutenderera uye warehousing system.

Hegerls tekinoroji

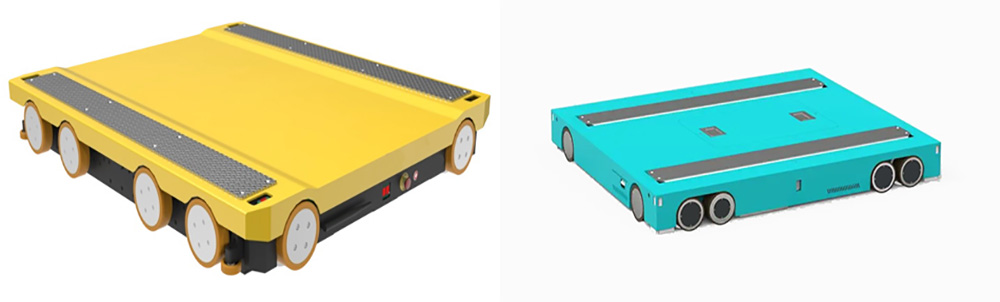

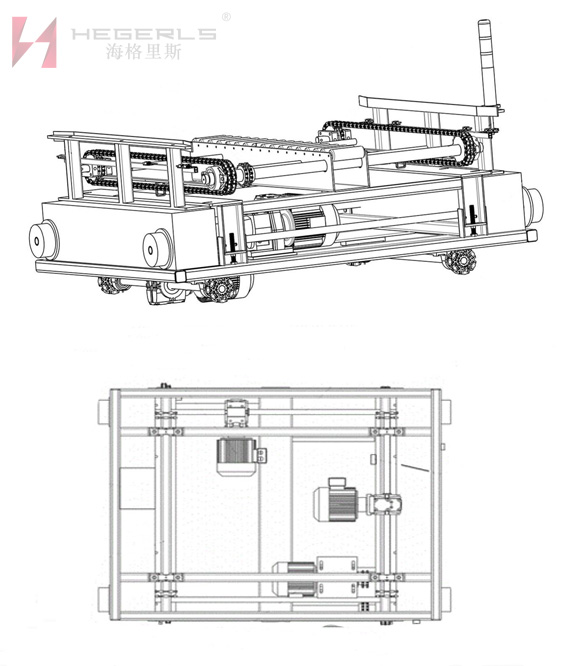

Hebei Woke ane nhoroondo yeanopfuura makore makumi maviri ebudiriro.Yayo yakazvimiririra mhando, Hegerls, yakagadzira uye yakaisa mukushandisa yekutanga yakangwara nzira ina-shuttle robhoti ichishandisa yayo tekinoroji.Kusvika iye zvino, yakagadzira marobhoti akangwara mana-marobhoti, inotonhora yekuchengetera yakananga akangwara mana-nzira marobhoti evhavha, anorema-basa akangwara mana-nzira marobhoti evhavha, stacker zvinhu zvinobata marobhoti, yakakwirira-chaiyo elevator, uye zvine chekuita nekutsigira masisitimu.

Pakati pavo, iyo yakazara otomatiki yakangwara dense yekuchengetedza uye yekufambisa sisitimu yakazvimiririra yakagadziridzwa neHEGERLS tekinoroji uye yakangwara ina-nzira yeshuttle robhoti, senzira yekuvandudza yemasherufu masherufu, haina kungokodzera maindasitiri ane mashoma maSKU uye matura akakura emhando imwe chete akashumirwa. nemasherufu echinyakare, asi zvakare anogona kuchinjika kugadzira sherufu kudzika.Nekushandisa musanganiswa wenzvimbo dzakadzama dzakawanda pamasherufu, sisitimu iyi inogona kuwana kuchengetedzwa kwakaomarara kwemhando yeABC zvinhu pasherufu imwe chete.

Iyo HEGERLS yakangwara tireyi ina-nzira yekuvhara sisitimu yakaburitswa naHebei Woke mhinduro inoshanduka yakatarisana nekuchengetedza tireyi uye kubata mamiriro.Vashandisi vanogona kusanganisa iwo sezvivharo zvekuvaka, uye kuwana "mota imwe inomhanyisa imba yese yekuchengetera".Ivo vanogona zvakare kuwedzera kana kudzikisa mota zvinoenderana nekuchinja kuri kudiwa panguva yemwaka wepamusoro uye kukura kwebhizinesi.Panguva imwe chete kutora akawanda-level Hardware uye software yekutarisa matanho, kuseta nzendo dzekutyaira dzakachengeteka uye misimboti yekutonga, uye kuve nechokwadi chekushanda kwakachengeteka kwemotokari yese kuburikidza neakananga madhiraivha ekutyaira kana anti kupidigura nzira.

Iyo HEGERLS pallet ina-nzira shuttle ine yakanakisa kuchinjika, iyo inogona kuchinjika kune mamiriro ane yakakwirira uye yakaderera frequency yeinopinda uye inobuda mashandiro.Zvinogona kutaurwa kuti tekinoroji iyi ndiyo yakanakisa yekuwedzera kune AS / RS system.Pamusoro pezvo, tireyi ina-nzira yekuvhara sisitimu ine yakanakisa dense yekuchengetedza simba, iri nani pane yechinyakare AS/RS, uye inonyanya kukodzera mamiriro ane yakaderera nzvimbo yekuchengetera (kazhinji isingasviki 15M, AS/RS haina kukodzera), ichiita. yakakurumbira mune inotonhora cheni masisitimu.

Kugonesa mabhizinesi kuderedza mitengo uye kuwedzera kushanda zvakanaka

Parizvino, HEGERLS yakangwara tray ina-nzira yekuvhara system yakaitwa mune mamwe matura.Zvinoenderana neyakayerwa data kubva kune yakapfuura bhizimusi rekugadzira zvinhu, pasi penzvimbo imwechete yekuchengetera, uchishandisa stacker crane yekuchengetera mhinduro inogona kuwana 8000 nzvimbo dzekuchengetera, nepo uchishandisa pallet yenzira ina yekuvharira yekuchengetera mhinduro inogona kuwana 10000 nzvimbo dzekuchengetera, ine nzvimbo. kuwedzera kwehuwandu hwekushandiswa kwepamusoro pe20%.

Mukuwedzera, nekuda kwezvinodiwa zvakasiyana-siyana zvepallets zvichienzaniswa ne stackers, nzira ina yekuvhara inogona kushandisa mapeti akaonda, ayo anogona kuchengetedza pamusoro pe40% yemari yepallet;Panyaya yekushandiswa kwesimba, tray-way shuttle inogona kuchengetedza kupfuura 65% yemamwe mari;Panyaya yekutenderera kwekuvaka iyo vashandisi vebhizinesi vari kunyanya kunetsekana nazvo, kutenderera kweiyo nzira ina yekuvhara marori ekuchengetedza marori epallets inogona kudzorwa mukati memwedzi mishanu, iyo inogona kupfupikiswa neinopfuura 50% kana ichienzaniswa neiyo stacker crane kuchengetedza. mhinduro.

Kubva pane zvakatevedzana zvezviitiko zvakaita sekutenderera kweprojekiti, kushandiswa kwesimba, huwandu hwekutakura, uye mutengo wepallet, iyo nzira ina yekuvhara sisitimu yemapallet ndiyo inodhura-inoshanda mhinduro, iyo inogona kubatsira vashandisi vebhizinesi kuwana kuderedzwa kwemutengo uye kuvandudza mashandiro.

Nguva yekutumira: Jan-09-2024