Nekukurumidza kukura kweiyo indasitiri yemazuva ano yekutakura zvinhu, iyo ina-nzira ina yekuvharira mota matatu-dimensional warehouse yave imwe yemhando dzemhando dzeatomatiki matatu-dimensional matura nekuda kwemabhenefiti ayo mune inoshanda uye yakaoma kuchengetedza mabasa, mari yekushandisa, uye yakarongeka yakangwara. maneja mune warehousing system.

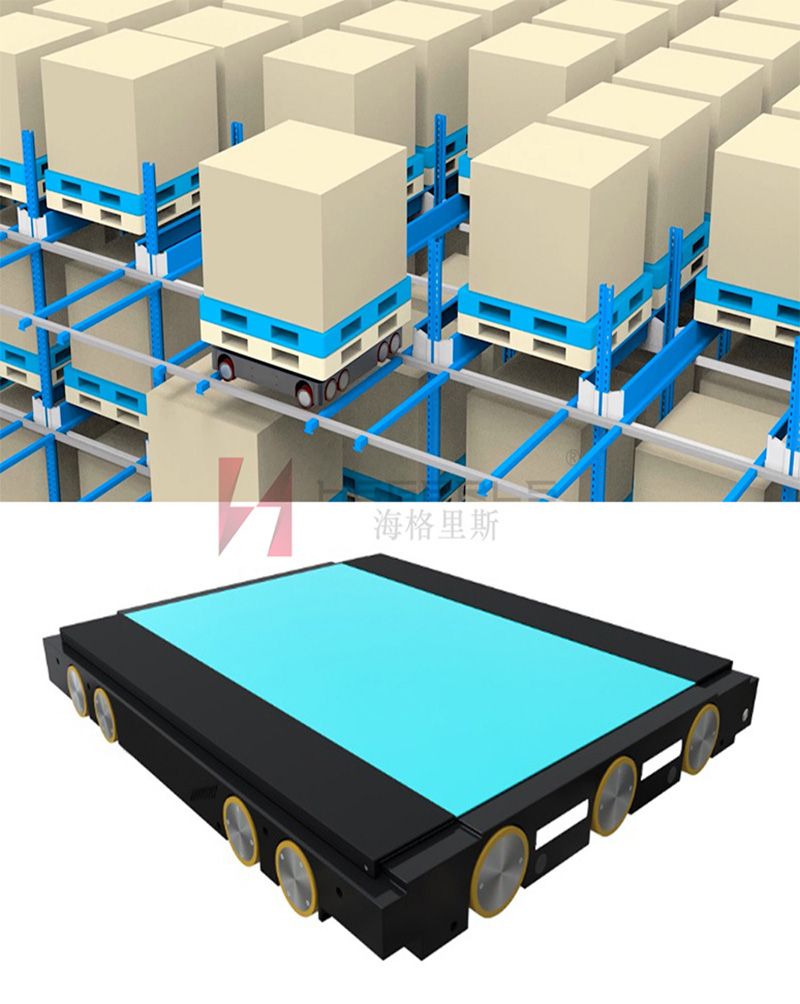

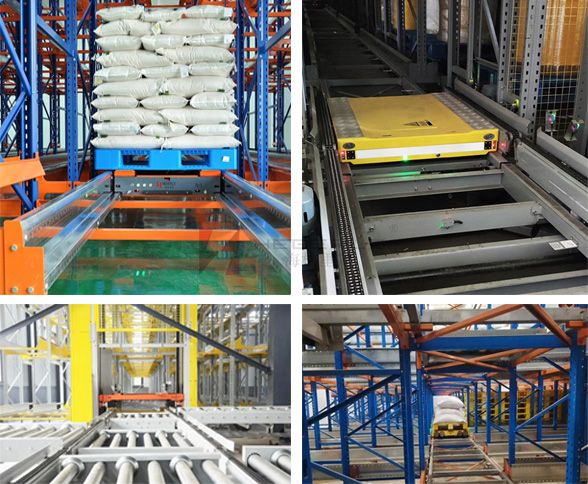

Iyo ina-nzira ina yekuvharira mota matatu-dimensional warehouse imhando yeatomatiki matatu-dimensional warehouse, inosanganisira ina-nzira yekufambisa mota, matatu-dimensional masherufu, elevator, tray conveyor mitsara, kusimudza uye kutamisa michina, uye software control system. .Chikamu chesherufu chinoshandiswa kuchengetedza zvinhu, nzira ina yekuvhara inoshandiswa kutakura zvinhu pasherufu, uye software yekutonga system inoshandiswa kudzora kushanda kwechina-way shuttle uye zvimwe zvigadzirwa zve automation, uye kunyora mamiriro chaiwo. zvezvinhu.Iyo ina-nzira ina yekuvharira mota matatu-dimensional warehouse ndeye yakajairika otomatiki matatu-dimensional warehouse mhinduro inogona kuiswa kune isina kujairika, isina kujairika, hombe chikamu chiyero kana diki akasiyana hombe batch, akawanda akasiyana mahombe matura edzimba.Nekushandisa iyo yakatwasuka uye yakachinjika kufamba kwechina-nzira yekuvharira mota uye kushanda pamwe neelevator yekuchinja dhizaini, kuchengetedza otomatiki uye kudzoreredza kwezvinhu kunogona kuwanikwa, iyo inokodzera kuyerera kwakaderera uye yakakwirira density kuchengetedza pamwe nekuyerera kwakanyanya uye high density kuchengetedza.Iyo ina-nzira yekuvhara matatu-dimensional warehousing system imhando nyowani yehungwaru yekuchengetera sisitimu inobatanidza akawanda mabasa akadai seatomatiki stacking, otomatiki kubata, uye isina munhu kutungamira.Nekukurumidza kusimudzira kwekuchengetedza zvinhu uye e-commerce maindasitiri, yakashandiswa zvakanyanya.

Iyo matatu-dimensional imba yekuchengetera yenzira ina-yevhavha mota yakanyanya kuomarara mukutonga kuronga, kurongeka manejimendi, nzira optimization algorithms, uye zvimwe zvinhu, zvichiita kuti kuita kweprojekiti kuome.Naizvozvo, kune vashoma vatengesi, uye Hebei Woke Metal Products Co., Ltd. (yega ega brand: HEGERLS) mumwe wevashoma vatengesi.

Kuenzaniswa neyemanyorero masherufu esherufu yekuchengetera uye kutumira, iyo nzira ina yekuvharisa mhinduro yakashandura yakafuratira "zvinhu kuvanhu" sisitimu kuita akawanda-layer 3D "zvinhu kuvanhu" system, ichigadzira otomatiki-matatu-matatu imba yekuchengetera ine yakakwirira uye denser kuchengetedza. nzvimbo.Iyo HEGERLS ina-nzira yekuvhara matatu-dimensional warehouse mhinduro inokodzera kuchengetwa kwezvakatemwa zvemotokari senge pallets, mabhini, uye makadhibhokisi mabhokisi, uye inokodzera kwakasiyana kwakaomarara kurongeka kwenzvimbo uye mamiriro eindasitiri.Mune imwecheteyo spatial marongerwo system, iyo HEGERLS ina-nzira yekuvhara mota matatu-dimensional warehouse system ine yakakwirira dhigirii ye automation uye yakasimba inbound uye kunze kwekugadzirisa kugona zvichienzaniswa neyechinyakare warehousing masisitimu, ayo anogona kupfupisa zvakanyanya basa rekugadzirisa nguva.

Kushanda maitiro eHEGERLS ina-nzira yekufambisa mota matatu-dimensional warehouse

1) Kuchengeta: Iyo tireyi yekuchengetera inoiswa yakananga pachiteshi chekuchengetedza kuburikidza neforogo, uye mushure mekudzvanya bhatani rekuchengetedza, mutsara wekutakura unoenda munzira yekuchengetera.Mushure mekutarisa chitarisiko, tarisa kana zvinhu zvakaiswa zvakanaka.Kana vakakodzera, vanozochengetwa nekuongororwa nemabarcode;Kana iyo isingakodzeri, inodzoserwa kudura uye zvinhu zvinorongedzerwa pamaoko.Iyo barcode scanner inotarisa iyo pallet kodhi.Mushure mekubudirira kuongorora, WCS (control system) inodzosera kukosha kwebhakodhi kuWMS.WMS (computer management information system) inopa nzvimbo inotakura zvinhu zvichienderana nebhakodhi kukosha uye inotumira kuWCS (kusanganisira ruzivo rwakadai sehuwandu hwematanho, mitsara, makoramu, nekudzika kwenzvimbo inotakura);WCS inotumira ruzivo rwenzvimbo inotakura zvinhu kuPLC;Iyo PLC inodzora mashandiro emutsetse wekutakura nekuwana kero yekuenda yekuchengetedza;Saizvozvo dzora hoist kutakura zvinhu kuenda kunzvimbo yekuenda.Kana iyo scanner ikatadza kuongorora kodhi, WCS ichapa mhinduro kuWMS pamhedzisiro yekutadza kwe scan, uye mutsara wekutakura unomira kumhanya uye kumirira kugadziridzwa kwemaoko;Kana iyo scan value yakatemerwa neWMS kuve isingaite, iyo conveyor mutsara inomira kushanda uye kumirira kugadziridzwa kwemanyorero;Vashandi vanogona kushandisa materminals anobatwa nemaoko kuongorora macode zvakare kana kutsiva ruzivo rwebhakodhi kubata mamiriro asina kujairika ekuongorora.Kana zvinhu zvichifanira kudzorerwa kuti zvigadziriswe, dzvanya bhatani re "return" pachiteshi chekuchengetera, uye zvinhu zvinodzoserwa kuchiteshi chekuchengetera kuti zvigadziriswe.

2) Rega kumirira kuti zvinhu zvifambe kune mutsetse wekutakura pamusuwo weelevator;Iyo PLC inosimbisa huwandu hwemasherufu akaturikidzana ayo zvinhu zvinoda kusvika zvichienderana nekero yekuenda kuchengetera, uye inofonera lifti.Kana elevator yasvika pauriri hwekutanga, mutsetse wekutakura unotakura zvinhu kuenda kune lifti, uye zvinhu zvinopfuura nemurifiti kuti zvisvike pauriri hwekuenda;Mushure mekunge lift yasvika padanho rekuenda, zvinhu zvinobuda muelevator pamwe netambo yekutakura uye inomirira rori kuti itore zvinhu pachiteshi chekutakura.

3) WMS (Computer Management Information System) inotumira mabasa anopinda nguva nenguva, uye WCS (Control System) inogamuchira mabasa anopinda uye inoaendesa kune inoenda shuttle mota yezvinhu;Iyo shuttle inogamuchira mirairo yemukati, inotyaira kuenda kunhanho yekukwira chiteshi kunotora zvinhu, uye nekuzvitakura kuenda kunzvimbo inotakura zvinhu.WMS (Computer Management Information System) inoburitsa basa rimwe panguva, uye WCS (Control System) inoita mabasa anopinda nekubuda anoenderana nekurongeka kwemabasa akapihwa neWMS (Computer Management Information System).Pamberi peWMS (Computer Management Information System) isati yaburitsa mabasa anopinda, zvinodikanwa kuti uone kana basa rinobuda rapera;Mushure mekupedzwa kwebasa rinobuda, iro rinopinda basa rinopihwa kudzivirira kufa kunokonzerwa nekugara kweiyo conveyor line zviwanikwa.

4) Inobuda: WMS (Computer Management Information System) inoburitsa mabasa anobuda (kusanganisira kero yekutanga uye kero yekuenda) kuWCS (Control System).Mushure mokunge WCS (Control System) yagamuchira basa rinobuda kunze, zvinhu zvinobuda zvinotakurwa nemotokari yemotokari pane imwe nzvimbo yezvino yezvinhu kune mutsara wekutakura weelevator;Zvinhu zvinomira kumirira pamutsetse wekutakura pamusuwo weelevator, nepo PLC ichidzora lifti kuti isvike pamwero wezvino wezvinhu;Mushure mekunge lifti yasvika pamwero wezvino wezvinhu, mutsetse wekutakura unotakura zvinhu kuenda kune elevator.Elevator inotakura zvinhu kusvika padanho rekutanga, uye zvinhu zvinobuda murefiti.Mutsetse weconveyor unotakura zvinhu kuenda pachiteshi chekubuda.Bvisa tireyi nemaoko wopedzisa nzira yekubuda nayo.

5) Kupinda kwewarehouse, kubuda, uye kuendesa (kubuda kunze, kufamba mukati) nzvimbo dzakapihwa neWMS system, uye dhizaini yekudzora hurongwa haitsigire kugovera nzvimbo;Kana paine tireyi inovharira mota yehungwaru panguva yekufamba kwayo, WMS inoda kutanga yaburitsa basa rekutamisa dura uye kubvisa tirayi yekuvharira isati yaburitsa mabasa anotevera.

6) Iyo otomatiki yekudzora sisitimu (WCS) inoita mabasa muhurongwa hwenguva yavo yakagamuchirwa, nemabasa akagamuchirwa ekutanga kuitwa.

7) WMS (Computer Management Information System) inoburitsa mabasa nguva nenguva, uye mushure mekuaisa pamberi mukati, WCS inoburitsa basa rimwechete nguva yega yega.

8) Kubudirira kwekuita kwe otomatiki midziyo yakanyatsoenderana nehurongwa hwekuchengetwa nekuiswa kwezvinhu, pamwe nenzira yekusiya imba yekuchengetera uye kudzika kwemugero.Idzi nzira dzinotarisa kushanda chaiko kwekupedzisira otomatiki michina.Kubudirira kwezvishandiso zveautomation kunoenderana nekubudirira kunowanikwa pasi pechigadziro chekushanda mune iri pamusoro.

9) Kana mota yekuvharisa pane imwe layer ikasashanda, mushure mekusimbisa nemaoko ruzivo rwekukanganisa, mota yakashata inogona kutamirwa kune imwe nzvimbo isingakanganise nzira dzinopinda uye dzinobuda.Mota dzisina basa pane mamwe maseru anogona kusimudzwa uye kutsiviwa kune yakashata mota layer kuti iite mabasa.

Hebei Woke, semugadziri anozivikanwa ane akakodzera tekinoroji tekinoroji patents, akaisa mari yakawanda mukutsvagisa nekusimudzira uye kusimudzira yakabatana yakangwara michina tekinoroji gore rega rega.Yayo brand HEGERLS fekitori ine otomatiki mitsara yekugadzira uye nehungwaru manejimendi, uye ikozvino yaenda pasi rose.Yakavimbwa nevatengi vazhinji munyika nematunhu akadai seEurope, America, Middle East, Latin America, uye Southeast Asia, uye yakazvigadzira yakazvimiririra uye yakagadzira yakangwara mota dzevhavha Multilayer shuttle mota, mubereki-mwana mota dzekufambisa, nzira ina. mota dzeshuttle, uye tunnel stackers dzave dzakagadzwa otomatiki-mativi matatu-matatu emidziyo yemidziyo yemhando yemabhizinesi mazhinji.

Nguva yekutumira: May-15-2023