Nekukurumidza kusimudzira kweindasitiri yezvigadziriso, iyo pallet ina-nzira yekuvhara rack matatu-dimensional warehouse yakagadzira kuita imwe yemhando huru dzekuchengetera zvinhu nekuda kwemabhenefiti ayo ekuita uye akasimba kuchengetedza basa, mutengo wekushanda uye yakarongeka uye nehungwaru manejimendi mu. kutenderera uye kuchengetedza system. Mumakore achangopfuura, iyo hegerls intelligent pallet four-way shuttle shelf yakahwina kufarirwa nemabhizinesi mazhinji, uye yakaunganidza ruzivo rwekushandisa musimba idzva, kugadzira kwakangwara, zvekurapa, shangu uye mamwe maindasitiri. Saka, vatengi vemabhizinesi vasati vashandisa sherufu yenzira ina pallet shuttle yehaigris vanofanira kubvunza kuti haigris inogona sei kuve nechokwadi chekuti masherufu efour-way pallet shuttle sherufu inogona kushanda nemazvo? Iye zvino, kubva paunhu uye dhizaini inoshanda yepallet four-way shuttle shelf, haigris inonyatso ongorora uye inopindura kuti haigris ingaite sei kuti ive nechokwadi chekushanda kwakanaka kwepallet four-way shuttle shelf system?

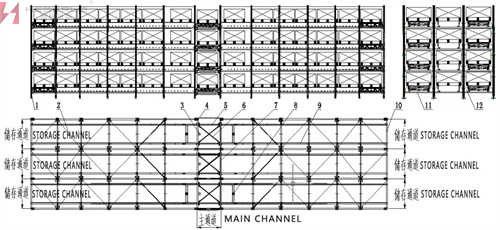

Iyo pallet yenzira ina yemotokari rack ndeye pallet ina-nzira yekuvhara rack, iyo inonyanya kuumbwa nezvidimbu zvakati twasa, matanda anotsigira, njanji njanji, njanji yevabereki, tsvimbo dzekudhonza, magumo ekutsigira, njanji dzinodzosera, nezvimwe.

1 - mbiru chidimbu 2 - yakachinjika tie tsvimbo ye sub track danda 3 - photoelectric positioning rutsigiro 4 - njanji inodzivirira pamagumo echiteshi chikuru 5 - njanji inodzosera shure 6 - muchinjikwa tambo yenjanji inodzokera kumashure 7 - njanji huru (ramp) 8 - kuchaja murwi 9 - sub track (tunnel) 10 - njanji inodzivirira pakupera kwe sub chiteshi 11 - inotsigira danda 12 - yekupedzisira rutsigiro

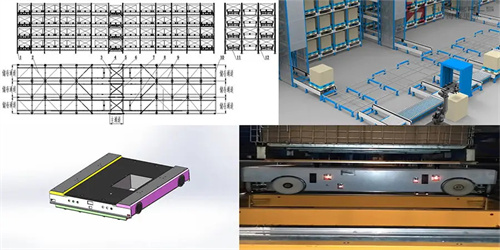

Iyo pallet ina-nzira shuttle otomatiki dense yekuchengetedza sisitimu ndiyo itsva otomatiki yekuchengetedza system mhinduro. Inogona kuona akasiyana otomatiki ekuchengetedza mabasa kuburikidza neinochinjika gadziriso. Inogona kugadzirwa seyakaomesesa yekuchengetera shuttle rack, laneway otomatiki matatu-dimensional warehouse rack, uye akasiyana masisitimu ekufambisa. Iyo sisitimu inokodzera otomatiki shanduko yepasi warehouse, warehouse ine akawandisa makoramu uye warehouse ine isina kurongeka chimiro. Zvinoenderana nezvinodiwa chaizvo zvekushanda kwekushanda, huwandu hwemidziyo inogona kugadzirwa zvinoenderana nezvinodiwa, kuitira kugadzirisa kusakosha kwemutengo wepamusoro wekugadzirisa uye yakaoma mechini chimiro cheiyo iripo otomatiki matatu-dimensional warehouse.

Mubvunzo: semupi ane hungwaru hwemidziyo yekushandisa, ndeapi maitiro epallet mhando ina-nzira yakangwara shuttle rack yakagadzirwa uye inogadzirwa nehegerls?

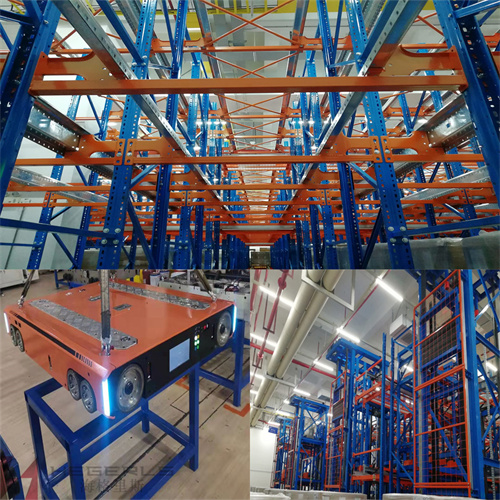

1) Iyo pallet ina-nzira shuttle ine compact chimiro: diki kureba uye saizi, kuchengetedza yakawanda yekuchengetedza nzvimbo; Iyo haingogone kufamba munzira ina pane inotsigira rack track, asi zvakare shandisa yakatwasuka lifti kuona iyo layer inoshandura mashandiro, izvo zvinowedzera kuwedzera kuchinjika uye scalability yewarehouse rack marongero uye mashandiro mune ina-nzira yekuvhara garaji.

2) Nzira ina dzekufamba: inogona kufamba nenzira dzakasimukira kana dzakachinjika patatu-dimensional rack yekuyambuka track kuti iwane imwe-stop point-to-point yekufambisa, uye inogona kusvika chero nzvimbo pauriri hweimba yekuchengetera;

3) Intelligent layer inotsiva: nerubatsiro rwehigris elevator, iyo shuttle mota inogona kuona inoshanda inoshanda maitiro otomatiki uye akarurama layer kutsiva; Ziva matatu-dimensional kufamba muchadenga uye kudzora nemazvo kuchengetera uye kubuda kweimwe neimwe nzvimbo inotakura musherufu yesimbi;

4) Intelligent control: ine otomatiki uye semi-otomatiki kushanda modes. Inonatsiridza zvakanyanya kushanda zvakanaka kwezvinhu zvinopinda uye kushandiswa kwenzvimbo kweimba yekuchengetera zvinhu. Iyo docking yeWMS uye WCs system software ine bhizinesi ERP / SAP / MES uye imwe manejimendi system software inogona zvakare kuchengetedza yekutanga mune yekutanga kunze nzira yekuchengetedza zvinhu, uye kubvisa kusagadzikana kana kushomeka kwemaitiro evanhu;

5) Mwero wekushandiswa kwakakwirira kwenzvimbo yekuchengetera: kuwanda kwechinyakare chekuchengetera nzvimbo kwakadzikira, zvichikonzera kuderera kwekushandiswa kwenzvimbo yekuchengetera nzvimbo uye kuderera kwekushandiswa kwehuwandu hwedura; Iyo pallet four-way shuttle mota inomhanya munzira ina pane main track murack, uye inogona kupedzisa oparesheni yakazvimirira pasina kurongeka kweforklift nemimwe michina. Sezvo huwandu hweiyo main track yeraki idiki pane vhoriyamu yeforklift operation chiteshi, iyo pallet ina-nzira shuttle otomatiki dense yekuchengetedza system inogona kuwedzera kuvandudza mwero wekushandiswa kwenzvimbo yekuchengetera zvichienzaniswa neyakajairika shuttle mota rack system, iyo. inogona kazhinji kuwedzera ne20% ~ 30%, inova 2 ~ 5 times iyo yeyakajairika imba yekuchengetera;

6) Simba rekutonga kwenzvimbo inotakura zvinhu: imba yekuchengetera yechinyakare ndiyo chete nzvimbo inochengeterwa zvinhu, uye kuchengetwa kwezvinhu ndiro basa rayo chete. Iyo imhando ye "static kuchengetedza". Iyo pallet four-way shuttle mota ndeye advanced otomatiki yekubata zvinhu zvekushandisa, izvo zvisingagone chete kuita kuti zvinhu zvichengeterwe otomatiki mudura zvichienderana nezvinodiwa, asi zvakare organic kubatanidza pamwe nekugadzira zvinongedzo kunze kweimba yekuchengetera, kuitira kuti igadzire yepamberi. Logistics system uye kuvandudza danho rekutonga rebhizinesi;

7) Unmanned otomatiki warehouse modhi: inoderedza zvakanyanya kuwanda kwebasa revashandi vekuchengetera uye inopa mukana webasa risina kurongwa mudura. Iyo-matatu-dimensional imba yekuchengetera chigadzirwa yakabatana zvakananga kuburikidza nepallet-nzira ina-yekutenderera-rwendo muchina, iyo yakatwasuka inosimudza yezvinhu uye otomatiki conveyor. Vashandi vekuchengetera zvinhu vanongoda kutarisa mashandiro ehurongwa nguva dzese kuti vaone kuwana otomatiki, uye hapana chikonzero chekupinda mudura kuti ushande. Inonyanya kukodzera kuchengetwa kwedzimba dzekuchengetera dzisina kukodzera kuvharirwa kwenguva refu kwevashandi, Ndiyo nzira yekusimudzira ye-high-density storage uye automatic warehouse mune ramangwana.

8) Kupisa kwemamiriro ekunze: iyo pallet ina-nzira yekuvhara sherufu inogadzirwa nehegerls inogonawo kuwana maviri ezvakatipoteredza modes: yakajairika kushanda pasi pekuchengetedza kwepamusoro-tembiricha uye kuderera-kupisa kuchengetedza.

9) Kuita kwekuchengetedza: tora akawanda-level Hardware uye software yakasanganiswa yekutarisisa matanho, isa yakachengeteka mashandiro kureba uye misimboti yekutonga, uye ive nechokwadi chekushanda kwakachengeteka kwemotokari yese kuburikidza neayo oparesheni yekumisa blocker kana anti kupidigura michina.

Mubvunzo: kunze kwezvikamu zviri pamusoro apa, ndezvipi zvinyorwa zvemasherufu mana-pallet shuttle mune yakananga dhizaini yekuita kuti kuve nechokwadi chekushanda kwakanaka kwesherufu system yechina-nzira pallet shuttle?

Iyo rack yechina-nzira yekuvharira rori yehaigris pallet ine yakasarudzika mbiri mota yekutanga uye yekudzikisira modhi, iyo inogona kuona yakagadzikana kushanda pasi pekumhanya kwakanyanya uye kudzika. Panguva imwecheteyo, ine zvakare yakasarudzika mbiri yekuchaja modhi yekuchaja yakananga uye isina waya yekuchaja. Iyo yakananga yekuchaja modhi yakakodzera kune zvakajairika kugadzirwa nharaunda; Wireless kuchaja modhi inokodzera guruva-uchapupu uye kuputika-proof nharaunda.

Iyo inoshanda dhizaini maficha eiyo rack yechina-nzira shuttle rori yehaigris pallet ndeaya anotevera:

Breakpoint kuenderera mberi: kana mota ichiita basa rekurodha nekuburitsa, nekuda kwekutadza kwenguva pfupi isiri yehardware senge zvipingamupinyi uye kubviswa kwenetiweki, mota inongoramba ichiita basa risati rapera pasina kupindira kwevanhu mushure mekumirira munzvimbo yekutanga kusvika. kusajaira kunobviswa.

Kuchaja otomatiki & kudzokera kubasa: kana mota yakadzikira pane yakatarwa yakaderera kukosha kwebhatiri, ruzivo rwakakodzera rwebhatiri rwunozoiswa otomatiki kuWCs, uye maWC anotumira mota kuti iite basa rekuchaja. Mushure mekunge mota yabhadhariswa kukosha kwesimba rakaiswa, ruzivo rwesimba rwakakodzera ruchaiswa otomatiki kuWCs, uye maWC anotumira mota kuti itangezve basa.

Pallet maonero: mota ine mabasa epallet centering calibration uye pallet yekuona

Chipingamupinyi maonero: mota ine zvipingamupinyi kuona basa munzira ina, uye inogona kudzivirira zvipingamupinyi pachinhambwe chakareba uye kumira pachinhambwe chipfupi.

Kunzwa tembiricha yebhatiri: inoona tembiricha yebhatiri mumuviri wemotokari munguva chaiyo. Kana tembiricha yebhatiri ikadarika iyo yakakwira muganho, inodzosera ruzivo rwekushisa kwebhatiri kuWCS munguva chaiyo. WCS inotumira mota kuchiteshi chakakosha kunze kweimba yekuchengetera moto kudzivirira moto.

In situ inodzosera basa: ziva in-situ kudzoreredza kwemuviri wemotokari nekutsiva mavhiri anowirirana pamativi ese.

Nzira ina dzekufamba: inogona kufamba munzira ina dzeiyo yakatsaurirwa track yetatu-dimensional imba yekuchengetera uye inosvika chero nzvimbo yakatarwa yeimba yekuchengetera pasi pekutumirwa kweWCS.

Position calibration: Multi-sensor Detection, inowedzerwa neaviri-dimensional kodhi yemugero, kuti uwane chaiyo chinzvimbo.

Hungwaru kutumira madhizaini maitiro: WCS online otomatiki kutumira modhi, bhuku remoti rekudzora mashandiro maitiro uye kugadzirisa maitiro.

Kurara & kumuka modhi: mushure menguva refu yekumira, pinda yekurara mode kuchengetedza simba. Painoda kumhanya zvakare, inomuka yega.

Emergency magetsi ekupa kununura: pasi pemamiriro asina kujairika, kana bhatiri simba raita zero, shandisa magetsi ekukurumidzira, batidza mota brake, uye fambisa mota ichienda kunzvimbo inoenderana yekugadzirisa.

Status show & Alarm: marambi ekuratidzira anoiswa munzvimbo zhinji dzemotokari kuratidza zvakajeka nzvimbo dzakasiyana dzekushanda dzemotokari. Buzzer inoiswa kuti ipe alarm kana mota yatadza.

Kuonekwa kwekuchaja: kana mota yasvika panzvimbo yekuchaja, kusajairika kwekuchaja kunoitika panguva yekuchaja, uye ruzivo rusina kujairika runodzoserwa kuWCS munguva chaiyo.

Kubata kwemotokari: mavhiri akakosha e polyurethane anoshandiswa kumanikidza kuramba, kupfeka kuramba, kuramba kumanikidza uye kubatwa nekuvhunduka.

Nguva yekutumira: Aug-25-2022