Automated three-dimensional warehouse chikamu chakakosha che logistics. Iine akawanda mabhenefiti akadai sekuchengetedza ivhu, kuderedza kuwanda kwevashandi, kubvisa zvikanganiso, kuvandudza mwero wekuchengetedza otomatiki uye manejimendi, kuvandudza hunhu hwemanejimendi nevashandisi, kudzikisira kurasikirwa kwekuchengetedza uye kurasikirwa kwekufambisa, kudzikamisa kuseri kwemari yekushanda, nekuvandudza zvinhu. kushanda zvakanaka, Panguva imwecheteyo, iyo otomatiki-matatu-dimensional warehouse yakabatana neiyo fekitori level komputa management information system uye yakanyatsobatana neyakagadzirwa mutsara ndiyo yakakosha link yeCIMS (Computer Integrated Manufacturing System) uye FMS (inochinjika yekugadzira system). Iyo zvakare sisitimu inochengetedza otomatiki uye inotora kunze logistics pasina yakananga manual kupindira. Icho chigadzirwa chepamusoro-tekinoroji chekusimudzira nzanga yemazuva ano maindasitiri, uye zvakakosha kuti mabhizinesi avandudze kugadzirwa Kuderedzwa kwemitengo kunoita basa rakakosha.

Mumakore achangopfuura, nekuenderera mberi kwekuvandudzwa kwekugadzirwa kwemabhizinesi uye manejimendi, mabhizinesi mazhinji anoona kuti kuvandudzwa uye kurongeka kweiyo logistics system kwakakosha mukusimudzira mabhizinesi. Iyo stacker ndiyo inonyanya kukosha yekusimudza uye kurongedza midziyo mune otomatiki matatu-dimensional warehouse. Inogona kutakura zvinhu kubva kune imwe nzvimbo kuenda kune imwe kuburikidza nekushanda kwemanyorero, semi-otomatiki mashandiro kana yakazara-otomatiki mashandiro. Inogona kuvharira kumashure nekudzoka mune otomatiki-matatu-dimensional lane uye kuchengeta zvinhu pamukoto wekupinda mukati mekutakura zvinhu; Kana kuti zvakasiyana, bvisa zvinhu zviri mukamuri inotakura zvinhu uye wozvitakura kuenda kumugwagwa unoyambuka, kureva kuti, stacker njanji kana isina trackless trolley ine michina yekusimudza. Iyo stacker yakashongedzerwa nemota kutyaira iyo stacker kufamba uye kusimudza pallet. Kana iyo stacker yawana inodiwa nzvimbo yekutakura, inogona kusunda kana kudhonza zvikamu kana mabhokisi ekutakura mukati kana kunze kwerack. Iyo stacker ine sensor yekuona iyo yakachinjika kufamba kana kusimudza kureba kuti uone chinzvimbo uye kureba kwenzvimbo inotakura zvinhu, Dzimwe nguva unogona zvakare kuverenga zita rezvikamu mumudziyo uye mamwe akakodzera zvikamu ruzivo.

Nekuvandudzwa kwekombuta yekudzora tekinoroji uye otomatiki matatu-dimensional warehouse, kushandiswa kwe stacker kunowedzera uye kwakawedzera, kuita kwehunyanzvi kuri nani uye kuri nani, uye kureba kuri kuwedzera zvakare. Kusvika ikozvino, kureba kwe stacker kunogona kusvika 40m. Muchokwadi, kana isingarambidzwe nekuvakwa kweimba yekuchengetera uye mutengo, kureba kwe stacker kunogona kuve kusingabvumirwe. Iyo yekumhanyisa yekushanda ye stacker inogara ichivandudza. Parizvino, iyo yakatwasuka yekushanda kumhanya kweiyo stacker inosvika 200m / min (iyo stacker ine mutoro mudiki yasvika 300m / min), yekusimudza kumhanya inosvika 120m / min, uye telescopic kumhanya kweforogo inosvika 50m. / min.

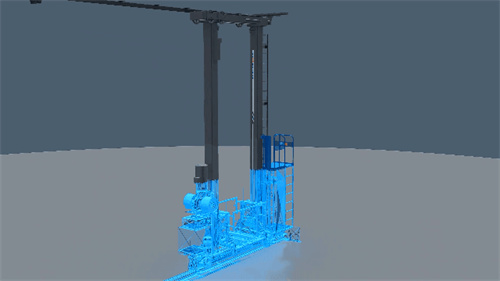

Kuumbwa kwe stacker

Iyo stacker inoumbwa nefuremu (yepamusoro danda, yakaderera danda uye mbiru), yakachinjika yekufambisa mashini, yekusimudza michina, chikuva chekutakura zvinhu, forogo uye yemagetsi control system. Mashoko acho ndeaya:

furemu

Iyo furemu irectangular furemu inoumbwa nedanda repamusoro, mbiru dzekuruboshwe nekurudyi uye danda rezasi, iro rinonyanya kushandiswa kubereka. Kuti zvive nyore kuiswa kwezvikamu uye kuderedza uremu hwe stacker, matanda epamusoro uye ezasi anogadzirwa nesimbi yechiteshi, uye mbiru dzakagadzirwa nesimbi square. Iyo yekumusoro crossbeam inopihwa yedenga njanji yekumisa uye buffer, uye yakaderera crossbeam inopihwa yepasi njanji yekumisa.

Operating mechanism

Iyo yekumhanyisa dhizaini ndiyo nzira yekutyaira yekufamba kwakatwasuka kwe stacker, iyo inowanzo umbwa nemota, coupling, brake, reducer uye kufamba vhiri. Inogona kupatsanurwa kuita pasi inomhanya mhando, yekumusoro inomhanya mhando uye yepakati inomhanya mhando zvichienderana nenzvimbo dzakasiyana dzekumhanya michina. Kana rudzi rwepasi runotambirwa, mavhiri mana anodiwa kuti amhanye pamwe chete nemonorail yakaiswa pasi. Iyo yepamusoro ye stacker inotungamirirwa nemaseti maviri emakumbo akatwasuka pamwe chete neI-beam yakagadziriswa padanda repamusoro. Danda repamusoro rakabatana nemabhaudhi nemakoramu, uye danda rezasi rakaiswa welded nechannel simbi uye simbi ndiro. Nzira yekufambisa yekufambisa, tenzi-muranda motokari vhiri, magetsi emagetsi, nezvimwe zvose zvakaiswa pairi. Mativi maviri edanda rezasi akashongedzerwawo nemabuffers kudzivirira stacker kubva pakuburitsa simba guru rekudhumhana nekuda kwekutadza kutonga kumativi ese emugero. Kana iyo stacker ichida kutora curve, kumwe kuvandudzwa kunogona kuitwa kune inotungamira njanji.

Kusimudza michina

Iyo yekusimudza meshini inyanzvi inoita kuti chikuva chekutakura zvinhu chifambe chakamira. Iyo inowanzo umbwa nemota, brake, reducer, chigubhu kana vhiri uye zvinochinjika zvikamu. Izvo zvinowanzo shandiswa zvinochinjika zvikamu zvinosanganisira simbi waya tambo uye yekusimudza cheni. Pamusoro peiyo general giya inodzikisira, iyo worm giya inoderedza uye inoderedza mapuraneti inoshandiswa nekuda kwekudiwa kwechiyero chakakura chekumhanya. Mazhinji emagetsi ekusimudza cheni ekutepfenyura akaiswa pamusoro pechikamu uye anowanzo akashongedzerwa neanopikisa kuderedza simba rekusimudza. Kuti uite iyo yekusimudza michina compact, mota ine brake inowanzoshandiswa. Iyo ketani yakanyatsobatanidzwa ne pallet kuburikidza negiya riri pambiru. The vertical lifting support component ndiyo column. Iyo column ndeye bhokisi dhizaini ine yekutanga anti distortion, uye gwara renjanji rinoiswa pamativi ese ekoromo. Iyo column inoshongedzerwa zvakare nepamusoro uye yakaderera muganho chinzvimbo switch uye zvimwe zvikamu.

Fork

Iyo inonyanya kuumbwa nemotokari inoderedza, sprocket, cheni yekubatanidza mudziyo, forogo ndiro, inofambiswa njanji njanji, yakagadziriswa njanji njanji, roller inotakura uye mamwe maturusi ekumisa. Iyo forogo mechanism ndiyo inotungamira nzira yekuti stacker iwane zvinhu. Iyo yakaiswa pane pallet ye stacker uye inogona kukwidziridzwa yakatwasuka uye kudzoserwa kuitira kutumira kana kuburitsa zvinhu kumativi maviri egidhi rekutakura. Kazhinji, maforogo akakamurwa kuita maforogo eforogo imwe chete, maforogo maviri eforogo kana maforogo akawanda zvichienderana nehuwandu hweforogo, uye maforogo akawanda anonyanya kushandiswa kurongedza zvinhu zvakakosha. Maforogo acho anonyanya kuita matatu-nhanho mutsara mutsauko telescopic maforogo, ayo anoumbwa nepamusoro forogo, yepakati forogo, yakaderera forogo uye tsono roller inotakura neinotungamira basa, kuitira kudzikisa upamhi hwemugwagwa uye kuita kuti ive yakakwana yekufamba telescopic. Iyo forogo inogona kukamurwa kuita mhando mbiri zvichienderana nechimiro chayo: giya rack modhi uye sprocket chain mode. The telescoping musimboti weforogo nderekuti forogo yezasi inoiswa papallet, iyo yepakati forogo inofambiswa negiya bar kana sprocket bar kuti iende kuruboshwe kana kurudyi kubva pakatarisana neforogo yepasi nehafu yehurefu hwayo, uye forogo yepamusoro inotambanukira kuruboshwe kana kurudyi kubva pakati peforogo yepakati nehurefu hwakati rebei kudarika hafu yehurefu hwayo pachayo. Iyo forogo yepamusoro inotyairwa nemaroller cheni maviri kana tambo dzewaya. Imwe mugumo weketani kana tambo yetambo inogadziriswa paforogo yezasi kana pallet, uye imwe mugumo inogadziriswa paforogo yepamusoro.

Kusimudza michina uye pallet

Iyo yekusimudza michina inonyanya kuumbwa nekusimudza mota (kusanganisira inoderedza), drive sprocket, drive cheni, kaviri sprocket, kusimudza cheni uye idler sprocket. Iyo ketani yekusimudza ndeye kaviri mutsara roller chain ine chengetedzo yakakura kupfuura 5. Inoumba chimiro chakavharwa chine idler sprocket pane pallet uye kumusoro uye pasi matanda. Kana mota yekusimudza ichityaira vhiri recheni mbiri kuti itenderere kuburikidza neketani yekutyaira, cheni yekusimudza inofambisa, nekudaro ichityaira chikuva chekusimudza (kusanganisira maforogo uye zvinhu) kusimuka nekudonha. Iyo mota yekusimudza inodzorwa nePLC frequency kutendeuka kudzivirira kushushikana kwakanyanya pacheni yekusimudza pakutanga kwekusimudza uye kumira. Chikuva chekutakura chinonyanya kugadzirwa neflat through uye welded steel plate, iyo inonyanya kushandiswa kuisa maforogo uye zvimwe zvekuchengetedza kuchengetedza. Kuti uve nechokwadi chekudzika nekudzika kwekufamba kwepallet, mavhiri mana ekutungamira uye maviri epamusoro mavhiri pamwe nekoramu akaiswa kune rumwe rutivi rwepallet.

Zvigadzirwa zvemagetsi uye kutonga

Iyo inonyanya kusanganisira yemagetsi drive, chiratidzo chekufambisa uye stacker control. Iyo stacker inotora inotsvedza yekubatanidza tambo yemagetsi ekupa; Sezvo simba rekupa sliding contact line carrier communication iri nyore kukanganiswa nemagetsi clutter, infrared communication mode ine yakanaka anti-kupindira inogamuchirwa kuchinjana ruzivo nekombuta nemimwe midziyo yekuchengetera zvinhu. Maitiro ekushanda kwe stacker ndeokuti inofanirwa kuiswa nenzira kwayo uye kugadziriswa, zvikasadaro zvinotora zvinhu zvisiri izvo, kukuvadza zvinhu nemasherufu, uye kukuvadza stacker pachayo mumatambudziko akakomba. Iyo chinzvimbo chekutonga kweiyo stacker inotora iyo yakazara kero yekuziva nzira, uye iyo laser renji yekutsvaga inoshandiswa kuona iyo ikozvino chinzvimbo cheiyo stacker nekuyera chinhambwe kubva kune stacker kuenda kunzvimbo yekutanga uye kuenzanisa iyo data yakachengetwa muPLC pamberi. Mutengo wacho wakakwirira, asi kuvimbika kwakakwirira.

Chengetedzo yekudzivirira mudziyo

Stacker imhando yemuchina wekusimudza, inoda kumhanya nekumhanya mumatanho akakwirira uye akamanikana. Kuti uve nechokwadi chekuchengetedza kwevashandi nemidziyo, iyo stacker inofanirwa kuve neyakakwana hardware uye software kuchengetedza zvishandiso, uye nhevedzano yekuvharirana uye kudzivirira matanho anotorwa mukutonga kwemagetsi. Midziyo mikuru yedziviriro yekudzivirira inosanganisira terminal kudzivirira muganho, kuvharira kuchengetedzwa, yakanaka chinzvimbo chekutarisa kudzora, cargo papuratifomu tambo yekupwanya dziviriro, simba-kudzima dziviriro, nezvimwe.

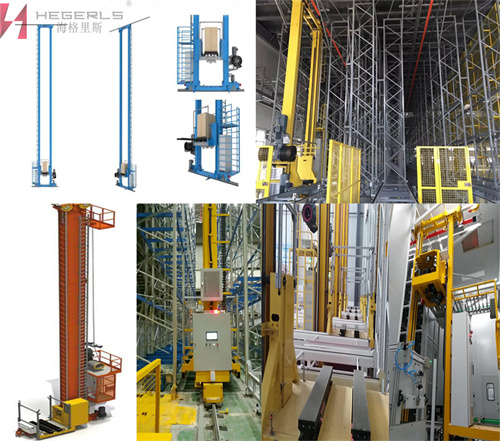

Kutsunga kwechimiro che stacker: kune akasiyana mafomu e stacker, anosanganisira monorail tunnel stacker, kaviri njanji mugero stacker, inotenderera tunnel stacker, single column stacker, kaviri column stacker, nezvimwe.

Kutsunga kwekumhanya kwe stacker: zvinoenderana nezvinodiwa zvekuyerera kweimba yekuchengetera, verenga iyo yakatwasuka kumhanya, kusimudza kumhanya uye forogo kumhanya kweiyo stacker.

Mamwe ma paramita uye gadziriso: iyo yekumisikidza modhi uye nzira yekukurukurirana ye stacker inosarudzwa zvinoenderana nesaiti mamiriro eimba yekuchengetera uye zvinodiwa nemushandisi. Kugadziriswa kwe stacker kunogona kuva yakakwirira kana kuderera, zvichienderana nemamiriro chaiwo.

Kushandisa otomatiki matatu-dimensional warehouse stacker

*Cherechedza kuchengetedza nzvimbo yekuvhiya yakachena uye yakachena, uye kuchenesa huruva, oiri uye mamwe mazuva ese.

* Sezvo iyo yekubata skrini uye zvimwe zvikamu zvemagetsi mupaneri yekushanda zviri nyore kukuvadzwa nehunyoro, ndapota zvichengetedze zvakachena.

*Paunenge uchichenesa pani yekuvhiya, zvinokurudzirwa kushandisa jira rakanyorova kupukuta, uye teerera kuti usashandise zvinosvibisa zvigadziriso zvakaita semafuta emafuta.

* Kana uchifambisa AGV, motokari inofanira kutanga yasimudzwa. Kana dhiraivha ikatadza kusimudzwa nekuda kwezvimwe zvikonzero, simba reAGV rinofanira kudzimwa. Izvo zvinorambidzwa zvachose kufambisa AGV kana dhiraivha yakavhurwa uye drive haina kusimudzwa.

* Kana iyo AGV ichida kumiswa munjodzi, bhatani rekukurumidzira richashandiswa. Zvinorambidzwa kushandisa kudhonza kana dzimwe nzira dzekuvhiringidza kumanikidza trolley yeAGV kumira.

*Hazvibvumidzwe kuisa chero chinhu pane oparesheni panel.

Kugadziriswa kwemazuva ese kweatomatiki matatu-dimensional warehouse stacker

* Yakachena sundries kana yekunze zvinhu mune stacker uye mugwagwa.

* Tarisa uone kana paine mafuta ekudonha padhiraivha, hoist uye fork zvinzvimbo.

*Tarisa pakamira tambo.

* Ziva kupfekwa kwechitima chegwara uye gidhi vhiri pane mbiru.

* Chenesa mwenje wemagetsi maziso / masensa akaiswa pane stacker.

* Basa rekuyedza remagetsi optical ziso / sensor yakaiswa pane stacker.

* Tarisa kutyaira uye vhiri mashandiro (kupfeka).

* Tarisa zvishandiso uye tarisa kana vhiri rekutsigira rakuvadzwa.

*Tarisa kuti hapana kutsemuka panzvimbo yewelding yekoramu yekubatanidza uye bhaudhi yekubatanidza.

*Tarisa nzvimbo yakachinjika yebhandi rine mazino.

* Tarisa iyo stacker inofamba.

* Tarisa uone basa rekupenda re stacker.

Nekuvandudzwa kwekugadzirwa kwemaindasitiri emazuva ano, mudura rematatu-dimensional, kushandiswa kwestacker kuchave kwakawedzera, kunyanya kushandiswa mukugadzira michina, kugadzira mota, indasitiri yemachira, njanji, fodya, zvekurapa nemamwe maindasitiri, nekuti maindasitiri aya achave. zvakanyanya kukodzera kushandiswa kwe otomatiki warehouse yekuchengetedza. Hagerls ibhizinesi rakazara rinotarisa mhinduro, dhizaini, kugadzira uye kuisa masevhisi ehungwaru yekuchengetedza uye nehungwaru zvinhu zvinotsigira otomatiki michina. Inogona kupa vatengi vane imwe chete column stacker, kaviri column stacker, inoshandura stacker, kaviri yekuwedzera stacker uye bin stacker uye mamwe marudzi emidziyo. Inogona kugadzirisa akasiyana marudzi emidziyo ye stacker zvinoenderana neyakasiyana zvigadzirwa, zvisinei nehukuru uye huremu.

Nguva yekutumira: Aug-18-2022